Overview

Sorting process technical requirements:

1) The voltage measurement range of a single battery meets: 0.0001-60 V.

2) Battery AC internal resistance measurement range : 0.01-10.00mΩ .

3) Calculation range of K3 value : 0.1-0.001mV/h.

K 3 (mV/ h ) = (voltage value of OCV 2 for incoming data extraction – real-time voltage value OCV 3 ) / (real time h 3 – test time of OCV 2 for incoming material extraction h 2 ).

4) Set up 1 OK channel, the OK product cells can be directly transferred to the post-processprocessing, respectively set up OCV-NG, DCR-NG, K-NG, 3 channels for NG products byscanning the code, and the number of buffer cells in a single NG channel is > 5 pcs.

5) Sorting has battery batch management (breakpoint management).

Technical requirements:

1) OCV test accuracy: ±0.01%rdg±3dgt , bias compensation is possible.

2) ACR test frequency: 1kHz±0.2Hz, test accuracy: ±0.5%rdg±10dgt (3.0000mΩ gear),±0.5%rdg±5dgt (other gears), four-wire measurement , bias compensation.

3) Test data is bound to the QR code of the battery cell, which can be traced back. The battery feeding batch can be set, and the feeding batch can be reflected in the traceability information table.

4) The machine can edit and set the sorting voltage range, internal resistance range, and K value range .

5) The machine has the function of picking out NG cells and transferring them to the corresponding NG channel. (When a single cell has multiple NGs, it will be placed in the first NG channel according to the priority of comparison, priority: Scan code > OCV > DCR > K ).

6) The machine has the function of counting the qualified rate of batteries and various NG rates according to the sorting batches.

7) Zero adjustment tooling is required.

8) The test instrument must use original accessories, and non-standard customized accessories and cables are not allowed.

9) The equipment has the functions of recording the number of times the test probe is used, setting the upper limit, and alarming.

10) Sorting capacity > 10 PPM.

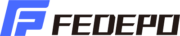

Basic Functions Introduction

The sorting machine is suitable for prismatic battery cells, manual loading, data binding by scanning battery codes , local data storage in ACCESS or SQL database and uploaded to the MES system according to customer process requirements. At the same time, it has the functions of scanning code , NG , automatic selection and discharge etc. The mechanical movement and data processing of this equipment are in the same system, and it is a highly automated and integrated equipment.

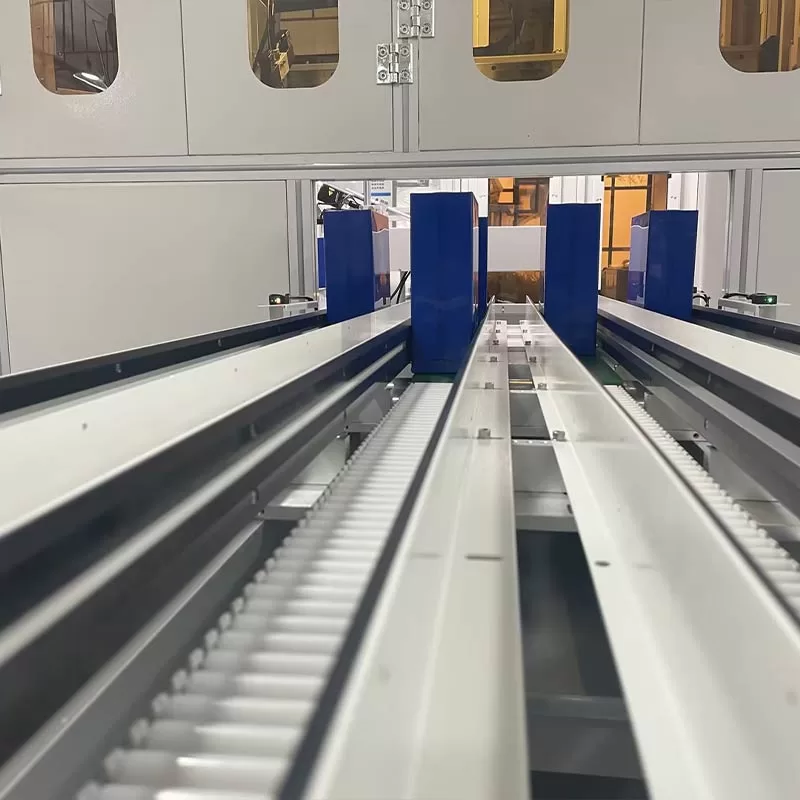

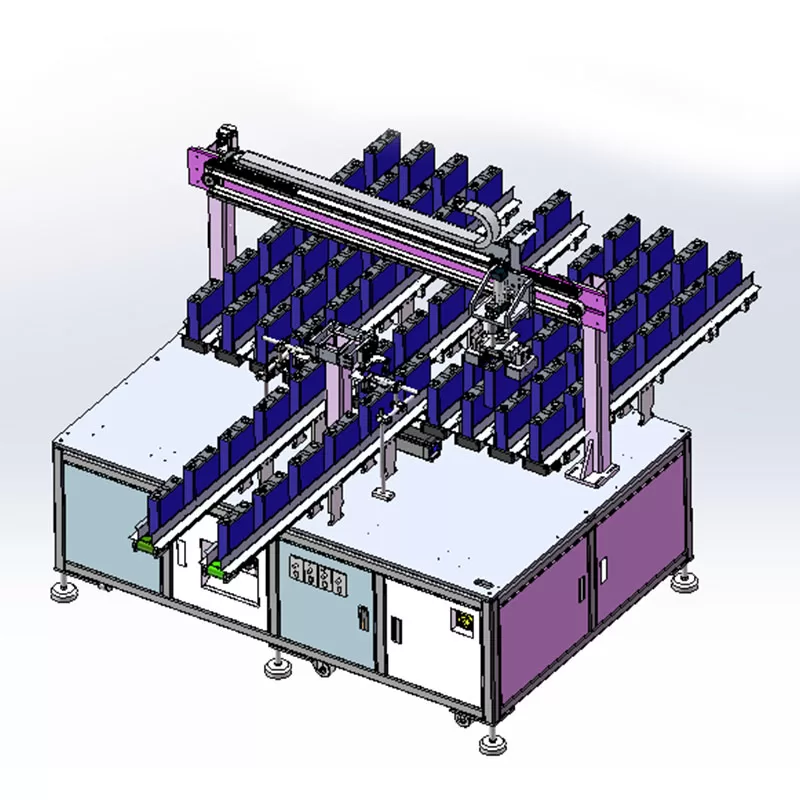

3D layout

Sorting machine 8OK+1NG

Basic parameters

| Item | Description | Basic Specifications | |

| Equipment Specifications | Number of channels | 9 | |

| Scan Meter | Keyence SR751 | ||

| Scanning accuracy | Maximum reading distance | 2D | 45~165mm (Unit size 0.5mm) focus Distance: 100mm |

| Barcode | 45~195mm (Unit size 0.5mm) Focal length: 100mm | ||

| Minimum decomposition energy | 2D | 0.19mm | |

| Barcode | 0.127mm | ||

| Equipment requirement | Power supply | Voltage AC220±5℅ 2KW | |

| Gas source | Compressed air 0.5~0.7MPa 0.6L/min (dry air) | ||

| Ambient temperature | 0-50℃ | ||

| Site | No pollution and strong electromagnetic interference | ||

| Humidity | Below 75% | ||

| Communication | Automatic saving of test data, data communication To communicate with customer’s MES | ||

| Battery code scanning | Automatic identification,naming and save | ||

| Equipment security | Abnormal air pressure | Alarm, manual processing | |

| Unqualified code scanning | Repeat scanning (scan code cycle can be set) | ||

| Unqualified continuous scan | Cell barcode NG is automatically picked out. | ||

| Reverse polarity | Cell barcode NG is automatically picked out. | ||

| Equipment safety door open | Equipment pause alarm prompt, manual processing | ||

| S/N | Item | Quantity | Unit | Brand |

| 1 | Cache belt | 9 | set | SHINHOP |

| 2 | Cabinet | 1 | set | SHINHOP |

| 3 | Cell position | 2 | Set | AirTAC |

| 4 | Electrical appliance | 1 | set | Inovance |

| 5 | PLC | 1 | set | Siemens /Inovance |

| 6 | Control touch screen | 1 | pc | Weinview |

| 7 | Servo motor | 9 | set | Inovance |

| 8 | Industrial computer | 1 | set | EVOC |

| 9 | Monitor | 1 | set | Dell |

| 10 | Scanning equipment | 2 | pc | Keyence /Hikvision |

| 11 | Module | 1 | set | SHINHOP |

| 12 | Detector | 1 | pc | HIOKI |

| 13 | Switching power supply | 1 | pc | MEAN WELL |

| 14 | Internal meter resistance | 1 | set | HIOKI |