Overview

Incoming specifications

Features

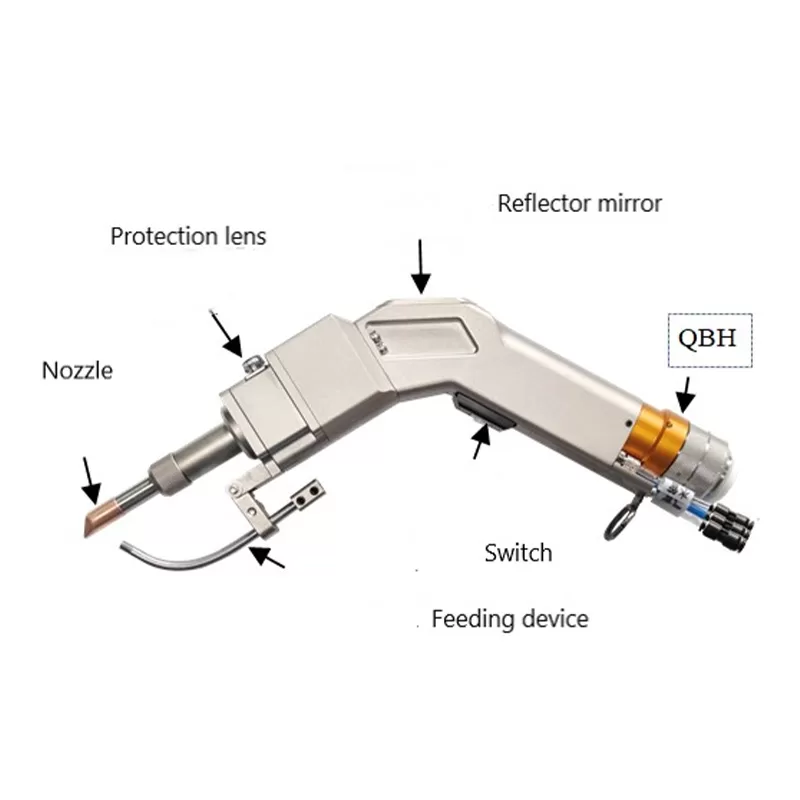

You can hold the laser welding head in your hand for welding operations. Due to the use of optical fiber transmission, the use distance can be appropriately expanded, and the welding angle is flexible, and it is easy to use. It is widely used in many hardware stainless steel structural parts.

Why is it said that it is a swing welding head?

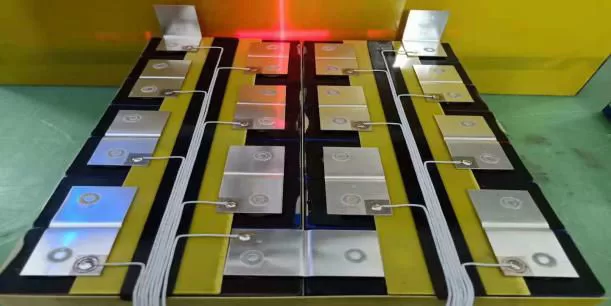

It’s not the oscillating welding head that you think, but the machine itself has an automatic oscillating system that can realize output such as light spot adjustment. Even if the welding gap is large, normal welding can be achieved. Normally, laser welding is butt welding. The requirements are relatively high, and generally need to be around 0.1MM. However, the swing type handheld laser welding machine is used, and the allowable range of the welding gap is larger and the welding effect is better.

Specific parameters

Power: 500W/1000W/1500W

Power adjustment: 10%-100%

Fiber core diameter: 100um/25um

Welding head: Type: swing laser welding head

| Laser power | 1000/1500/2000 watts |

| Laser source | Raycus / IPG |

| Welding head | Wobble welding head / Normal welding head |

| Laser frequency | 50Hz-5000Hz |

| Electric power | 220V50HZ / 380V 50Hz |

| Wavelength | 1070±5nm |

| Consumable part | Protection lens,focusing lens nozzle |

| Fiber leangth | 15m Standard |

| Cooling method | Water chiller |

| Dimension | 930x600x800mm |

| Beam quality | 1.1 |

| Laser power | 1000/1500/2000 watts |

| Laser source | Raycus / IPG |

| Welding head | Wobble welding head / Normal welding head |

| Laser frequency | 50Hz-5000Hz |

| Electric power | 220V50HZ / 380V 50Hz |

| Wavelength | 1070±5nm |

| Consumable part | Protection lens,focusing lens nozzle |

| Fiber leangth | 15m Standard |

| Cooling method | Water chiller |

| Dimension | 930x600x800mm |

| Gross weight | 260kg |

Advantages:

1. Light to move, easy to use,maintain and clean

2. The welding head adopts ergonomics, is light and easy to operate

3. Pure laser welding, better quality, higher efficiency, more reliable environmental protection

4. Wide range of welding materials, including stainless steel, carbon steel, aluminum and other materials

5. There are various welding types, which can be inner and outer right angle welding, splicing welding, stack welding, etc.