Configuration list

| S/N | Item | Description | Quantity | Unit | Brand |

| 1 | Motion device | 600*400*300mm | 1 | Set | HIWIN |

| 2 | Compression device | Flexible fixture | 1 | Set | Airtac |

| 3 | Jacking device | Pneumatic | 1 | Set | Airtac |

| 4 | Weld protection device | Water knife | 1 | Set | SHINHOP |

| 5 | Positioning device | Pneumatic | 1 | Set | Airtac |

| 6 | CCD monitor system | 1 | Pc | SHINHOP | |

| 7 | Control system | 1 | Set | SHINHOP | |

| 8 | Welding pressing tool | 1 | Pc | SHINHOP | |

| 9 | Laser source | Anti-reflection | 1 | Pc | Raycus |

| 10 | Galvanometer | High power precision scanner head | 1 | Pc | SHINHOP |

| 11 | Chiller | 4P | 1 | Pc | DOLUYO |

| 12 | Altimeter | HP-40 | 1 | Pc | Panasonic |

| 13 | Display | 1 | Pc | Dell | |

| 14 | Computer | 1 | Pc | EVOC |

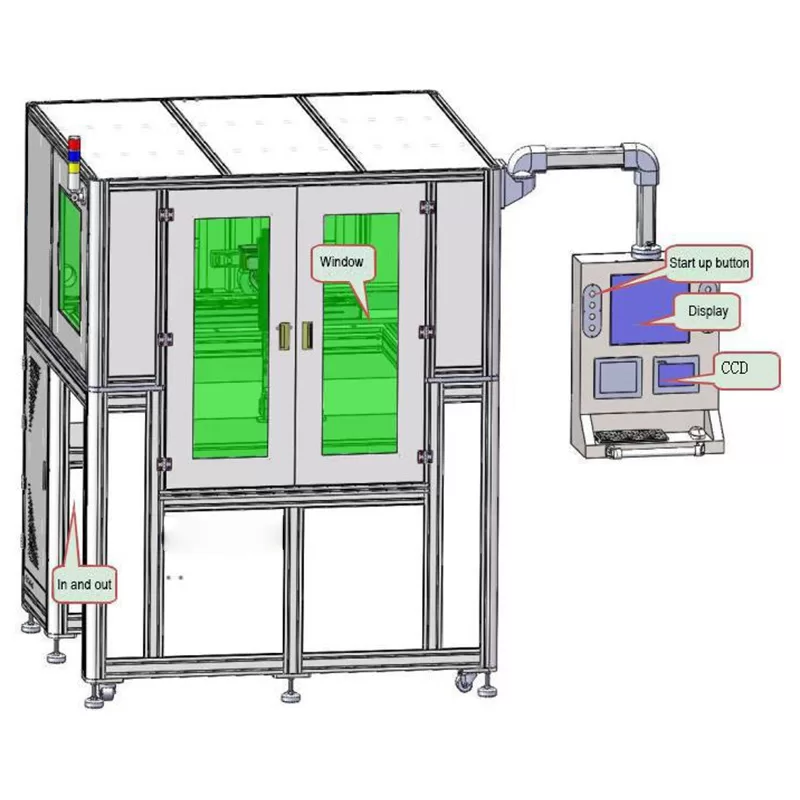

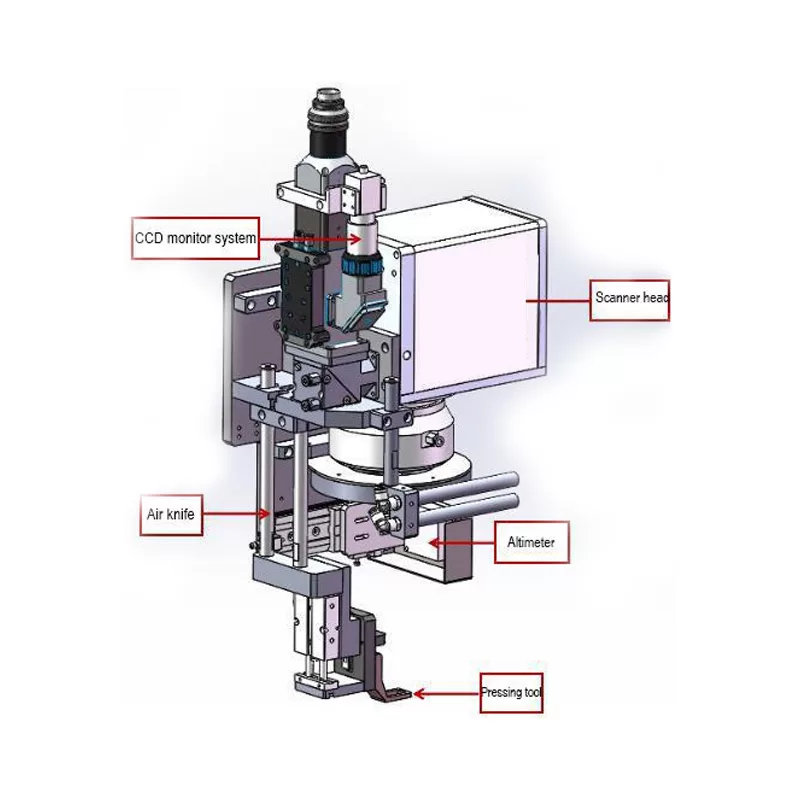

Compression device

The compression device is hoisted under the X axis and moves with the X axis and the Y1 axis and Y2 axis. The pressing tool is installed under two sets of compression cylinders. After the X axis and the Y1 axis & Y2 move to the station, the compression advice can alternately press the pole.

1 Vision is to take pictures of symbols through smart camera, and the integrated vision system feeds back real-time data on the welding trace of the product, and the trace are corrected due to various factors.

2 Height measurement, when there is a tolerance in the case of uneven battery

level, or tolerance caused by assembly, the height measurement system can be used

to measure the welding position of the upper and lower heights.

3 The pressing tool is made of copper and is driven by the cylinder. The automatic

laser focal length tracking system uses a high-precision laser displacement sensor.

The cylinder drives the sensor test head to move, and the cylinder presses the distance deviation. The sensor feeds back the data to the controller, and the controller sets the standard value according to the standard value.

4 The height of the Y-axis pressing device is adjusted with a scale, and the scale

hand wheel can be adjusted.

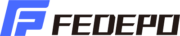

Welding control system

The control system is mainly composed of industrial computer, PLC, man-machine interface, according to different models, and the products are based on actual conditions.

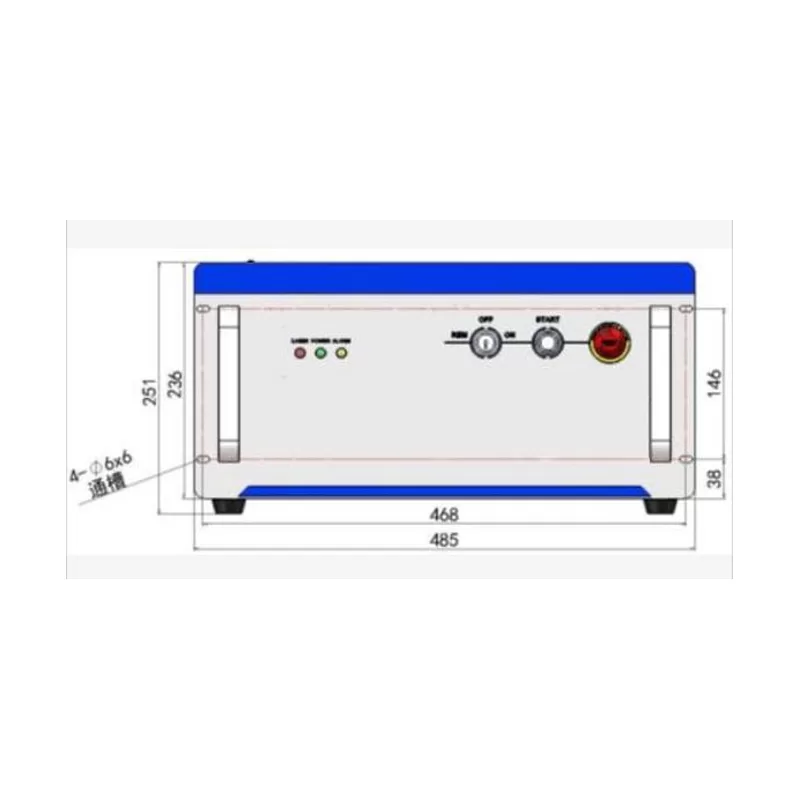

Laser size profile diagram

- Manual operation and automatic operation mode, linear and arc interpolation

- Adjustable welding parameters such as motion speed

- I/O signal test and monitoring

- Welding process and welding point position can be set through the man—machine interface

- Work piece origin can refer to mechanical origin setting

- The trajectory of welding joints on the battery can be selected (square, circle, polyline, etc). The batter cell layout and welding sequence can be selected and set by the coordinate grid on the battery pack model

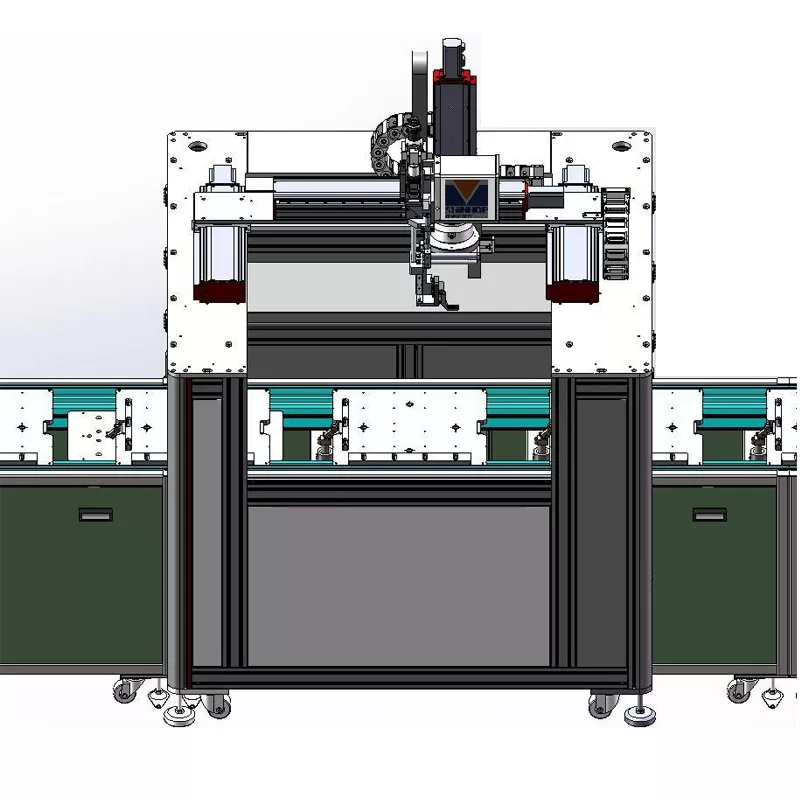

Laser system

Welding protection system

In order to prevent welding oxidation and improve welding quality and pass rate, the equipment is equipped with inert gas protection device. It adopts coaxial or paraxial air pipe, which is automatically or manually controlled by solenoid valve.

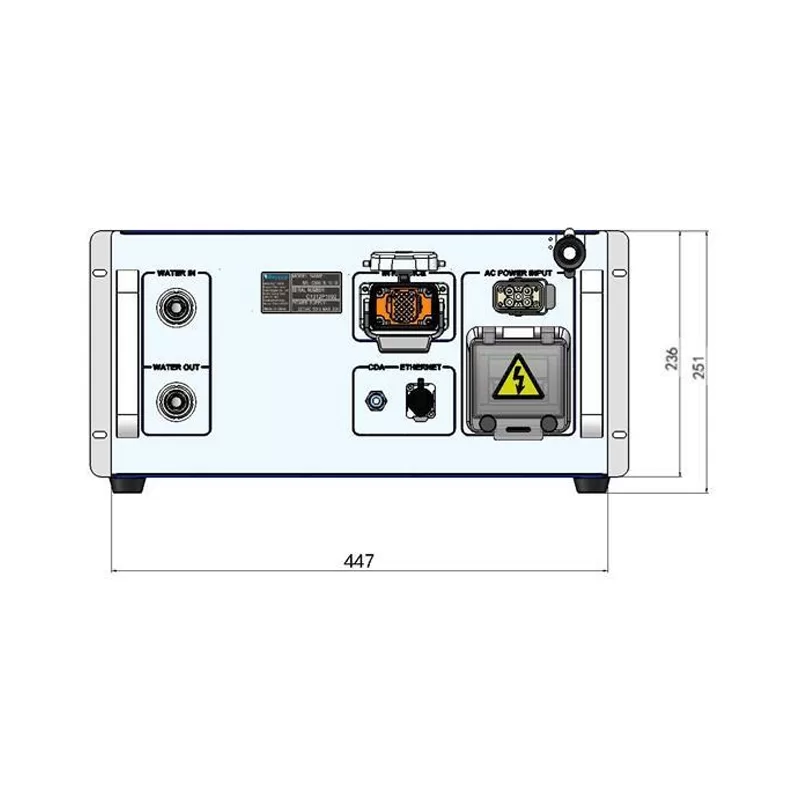

Laser size profile diagram

Front view:

Rear view:

(The actual product is subject to the customer's product)

The laser is 6000W CW laser. The relevant parameters are as follows:

| Average output power | 6000W |

| Center wavelength | 1080±10nm |

| Operation module | CW/Modulation |

| Maximum modulation frequency | 5KHz |

| Output power stability | <1% |

| Red light | Yes |

| Output connector | QBH |

| Output fiber length | 10M |

| Input power | 380V |

| Control mode | RS232/ ADRS232/AD |

| Power adjustable range | (10-100)% |

| Power consumption | 10000W |

| Weight | <100KG |

| Cooling method | Water cooling |

| Working temperature °C | 10-40 |

Galvanometer scanner system

- Modular design, simple unit replacement and matching

- The protective mirror is easy to clean and maintain

- Sealed design, dustproof and waterproof, long-term effective protection of lenses and optical fibers from pollution

- Water circulation cooling ensures continuous and stable work and prevents the temperature rise from affecting the laser energy output.

The galvanometer scanner head is as follows:

| Parameter item | Typical value |

| Scan angle | ±0.35rad |

| Tracking time | 0.7ms |

| Repeat positioning | <15urad |

| Gain drift | <50ppm/k |

| Positioning speed | 2m/s |

| Power supply | ±15V/5A |

| Operating temperature | 25±10°C |

| Physical dimension | 216mm*140mm*180mm |

| Weight | 7KG |

Chiller

Using the high-quality stainless steel cold water circulation

pump, large flow, high lift, low noise, long life; stainless steel

water tanks, pipelines, stainless steel valves will never worry

about rust; the control system adopts LCD full Chinese (or full

English) computer automatic control The operation is simple and

intuitive.

With automatic fault diagnosis function, the fault point is

directly displayed on the screen, prompting the user to deal with it

quickly; providing multiple protection functions and passive alarm

terminals, remote control terminals, easy to achieve centralized

control and monitoring.

The chiller below for your reference:

(The actual product is subject to the customer's product)

The chiller parameters are shown in the following table:

| Model | DLY6000 |

| Power supply system | 380V~/50HZ |

| Nominal cooling capacity | 17KW |

| Maximum operating current | 17.3A |

| Maximum operating power | 9.105KW |

| Water flow | >33L/min |

| Water control range | 8℃~30℃ |

| Water tank volume | 80L |

| Ambient temperature | 10℃~40℃ |

Fume collector

The fume collector is mainly composed of main body,

conveying pipe, smoking port, etc., which can realize the

functions of collecting, conveying and purifying the smoke and

dust generated by laser welding, and ensures the cleanness of

the welding space, thereby avoiding the smoke and dust

generated to affect the welding effect, during the welding process

from polluting the battery pack and laser welding head. The filter

adopts a spark-proof design and the filter material is

flame-retardant.

| Parameter | Typical value |

| Model No. | XL-500 |

| Layers No. | 6 |

| Voltage | 110V/220V |

| Power | 450W |

| Negative Pressure | 2500pa |

| Noise | <60dB |

| Systemic Flow | 700m3/h |

| Dimensions | 550 x 440 x 885mm |