Overview

Incoming specifications

1. The modules are composed of pouch cell, prismatic cell and some cylindrical cell pack.

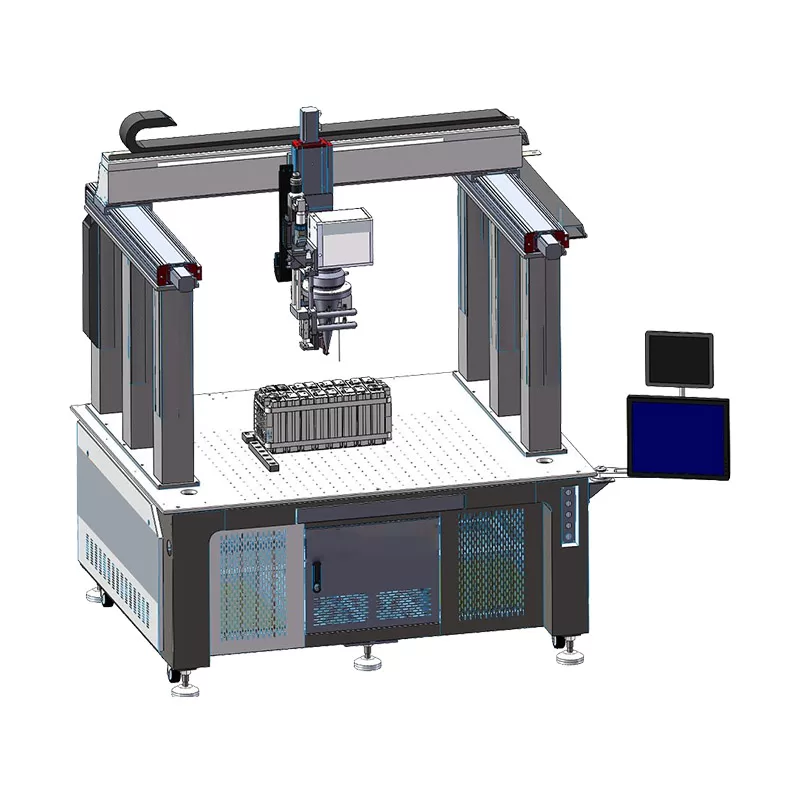

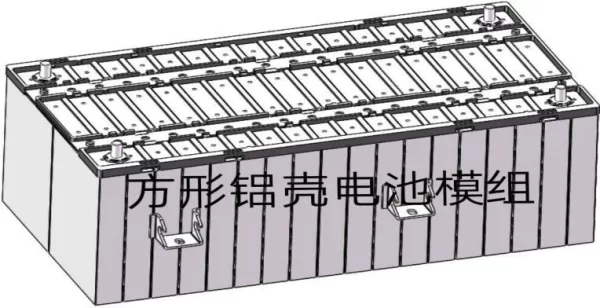

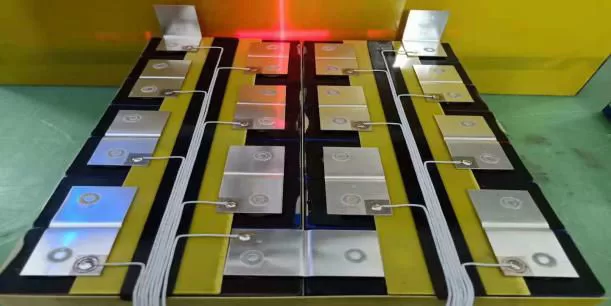

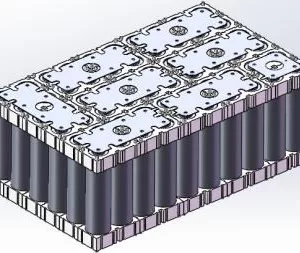

2. The module type is shown in the figure below: just for reference

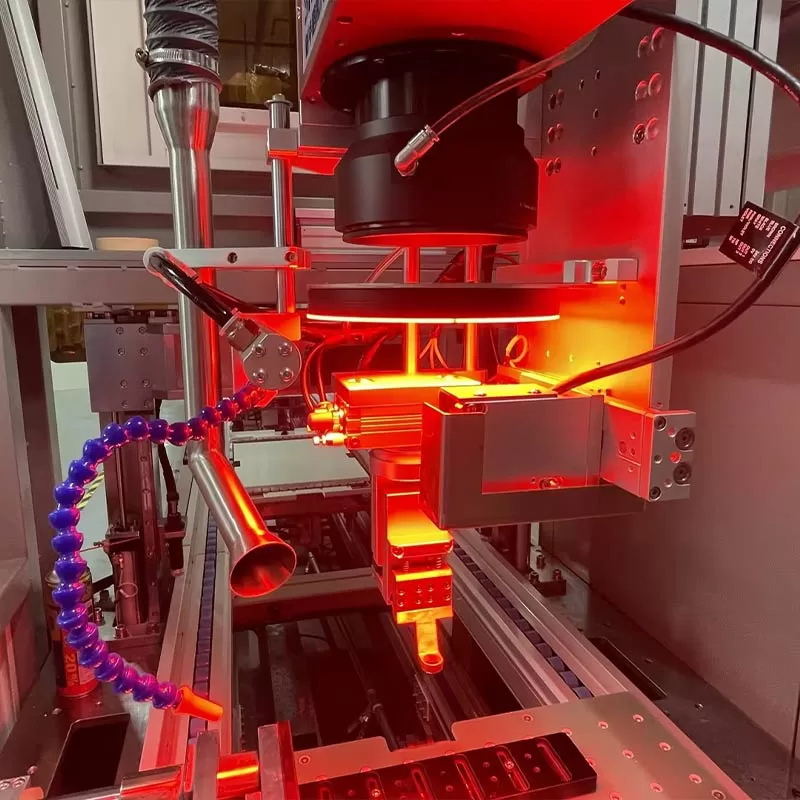

Prismatic cell pack laser welding apperance

Cylindrical cell pack laser welding apperance

(The actual product is subject to the customer's product)

Functional requirements

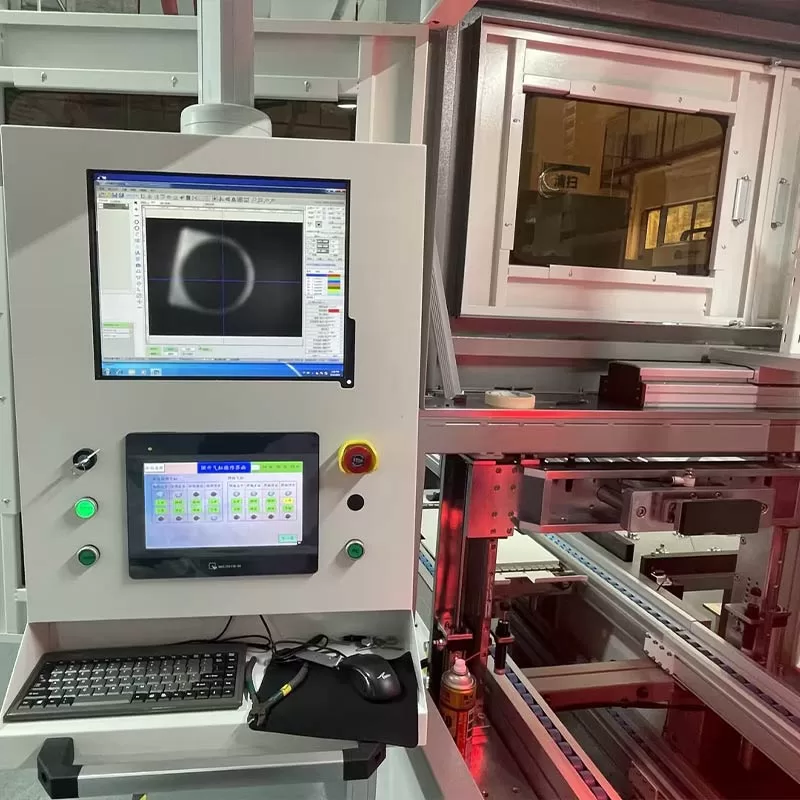

All visual and operation interfaces is English interface.

Compatible with pouch cell, prismatic cell and some cylindrical cell pack by adjusting the laser

power.

Laser welding machine technical requirement

This laser welding machine is mainly used for welding the prismatic or pouch pack. Welding material: aluminum, copper, nickel, etc. Welding seam is beautiful and welding seam width>1mm. A

protective cover is required around the welding machine, and a fume absorber device is required. In addition, a protective gas purge device is required.

The specific requirements of the equipment are as follows:

1)The welding thickness 3mm.

2)The stroke: X=1000mm, Y=800mm Z=400mm.

3)Welding speed≥1mm/s.

4)Laser type: CW.

5)Laser power: 6000W.

6)Laser working medium: optical fiber.

7)Laser working mode: single mode/multimode.

8)Laser service life: ≥5 years.

9)Pressing tool: 2pc for prismatic cell.

Process

- 1) Welding material: aluminum bus bar, copper bus bar, nickel tab.

- 2) Two modes of welding are available: CW and pulse spot welding.

- 3) Welding point penetration: 0.6±0.2mm or specified by Party A.

- 4) The tensile strength of welding point is greater than the destructive strength of material.

Equipment overview

The main equipment is shown in the following table:

| Equipment | Module welding station |

| Supply voltage (V) | 380±10%V AC 50/60Hz |

| Power supply capacity (kW) | 10 |

| Installation environment | Flat, no vibration and shock |

| Gas | Compressed air: pressure ≥ 0.6Mpa, Air consumption: 30 L/min; (According to the process) |

| Ground bearing requirements | ≥400kg/㎡ |

| Environmental requirements | Temperature 10-40℃; Humidity 30-70% |

| Failure rate | ≤3% |

| Pass rate | ≥98% (not including bad incoming materials) |

| Noise | ≤75db (measured at 1m from the machine) |

| Capacity | Calculated according to the cell and module size (how many pcs can be welded per minute) |

Main configuration

The main configuration is shown in the following table:

| Item | Part | Specification | Quantity | Remarks |

| Laser machine welding | Cabinet components | XHP-R6000G | 1 | Shinhop |

| Working table | Welding monitoring system | Magnify 20 times | 1 | Shinhop |

| Motion mechanism | X1000mm*Y800mm*Z400 mm | 1 | HIWIN | |

| Cabinet aluminum countertop | 1580*1300mm | National standard aluminum plate | ||

| Servo drive + motor | X axis 1000mm stroke 750W | INOVNCE | ||

| Servo drive + motor | Y axis 800mm stroke 400W | INOVNCE | ||

| Servo drive + motor | Z axis 400mm (with brake) 400W | INOVNCE | ||

| Control System | XHP1000 | 1 | Shinhop | |

| Laser | Laser | R6000W | 1 | Raycus |

| Welding head | laser galvanometer scanner | DGL-6000 | 1 | Shinhop |

| Pressing tool: | Prismatic cell | 2 | Shinhop | |

| Cooling | Laser independent chiller | Customized dual temperature dual control | 1 | DOLUYO |

| Fume extractor | XL-500 | 1 | QUBO |