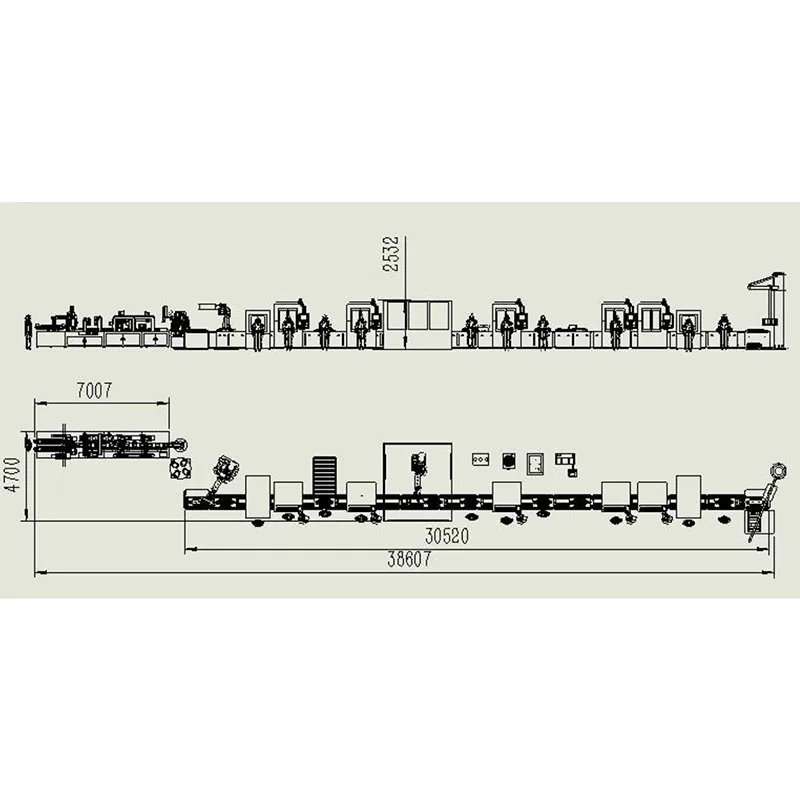

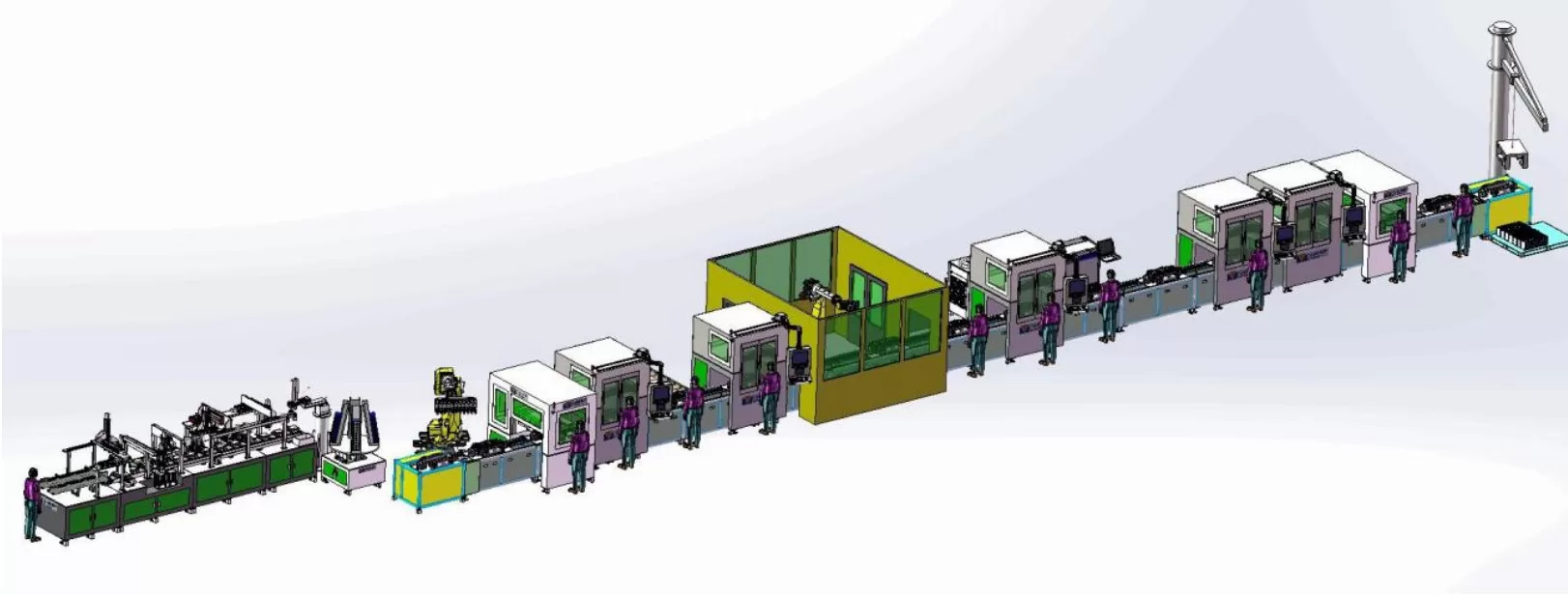

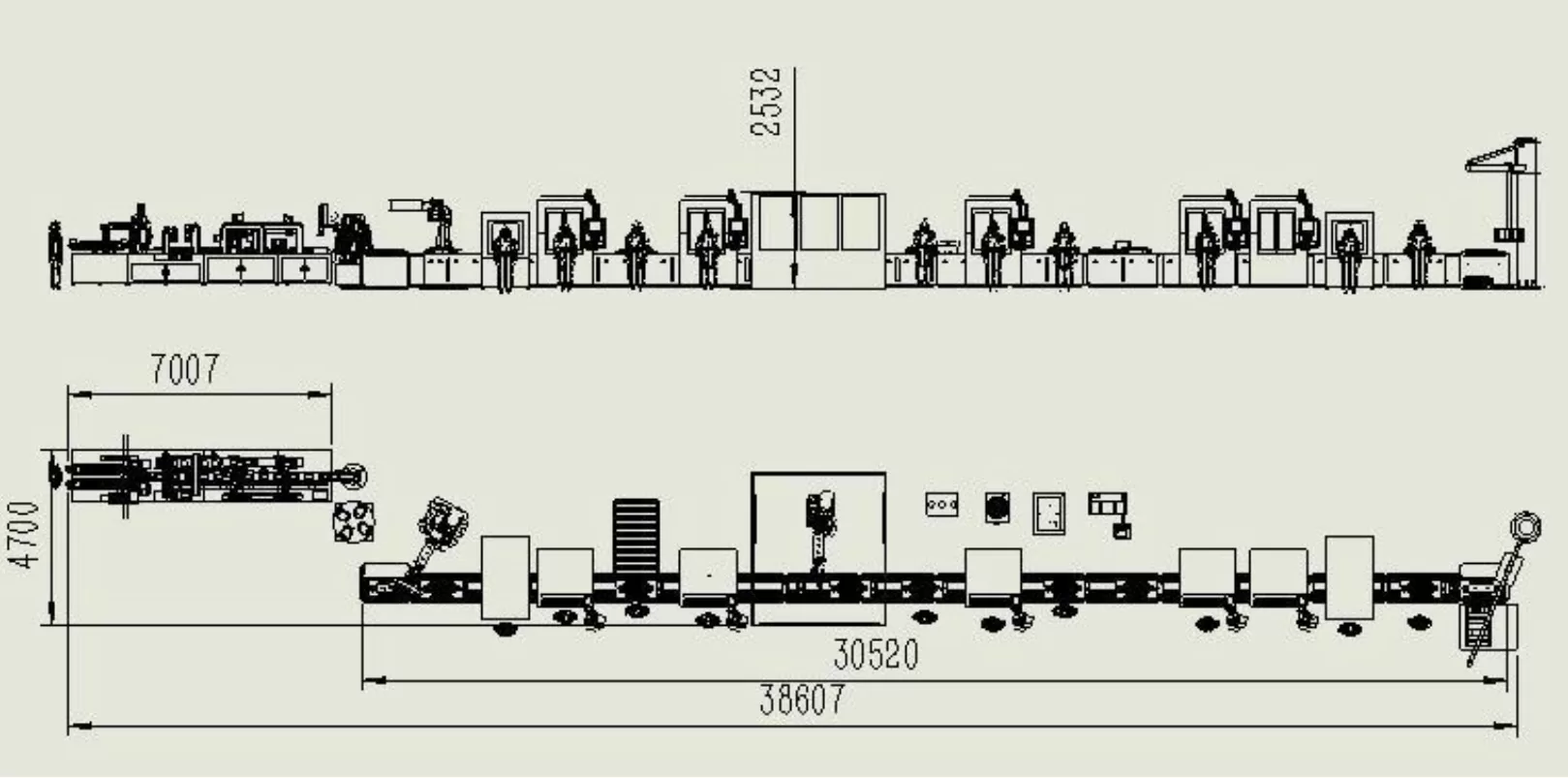

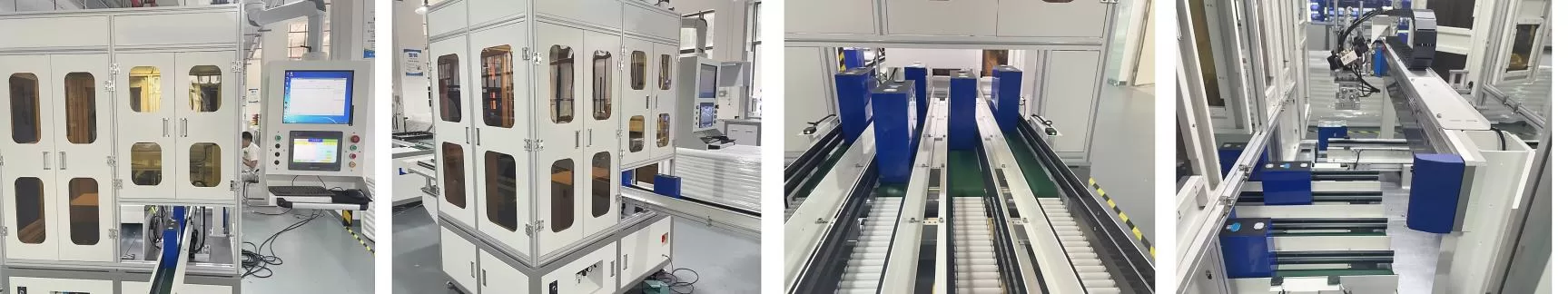

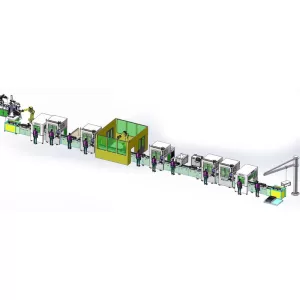

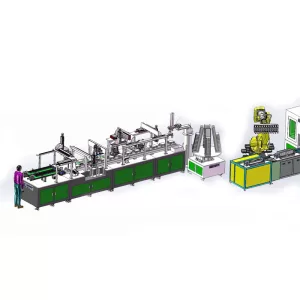

Lithium ion Battery Pack Assembly Line

Lithium ion Battery Pack Assembly Line

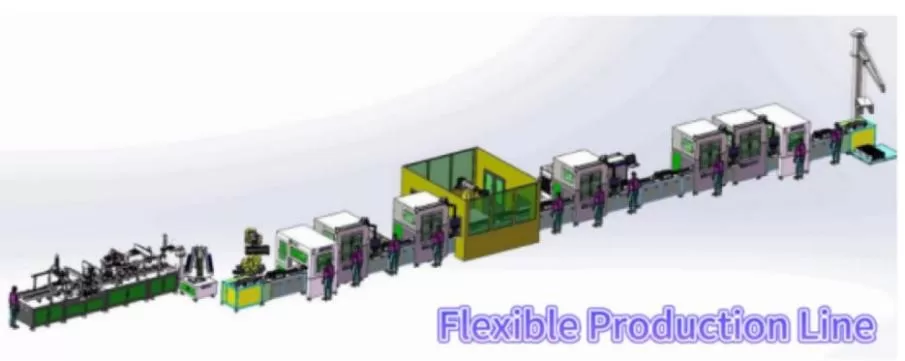

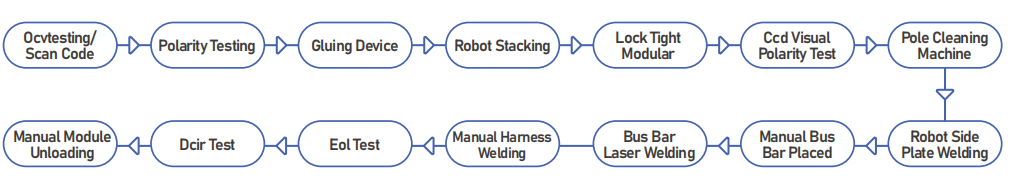

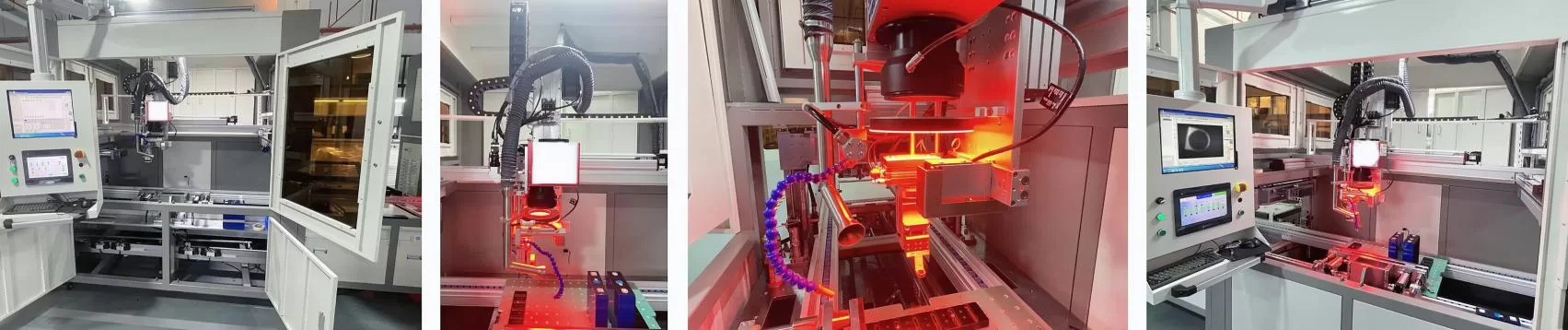

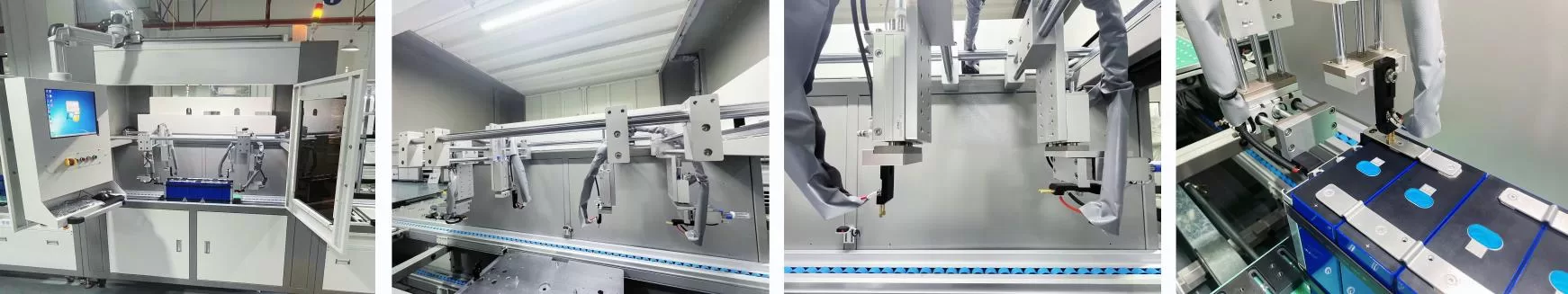

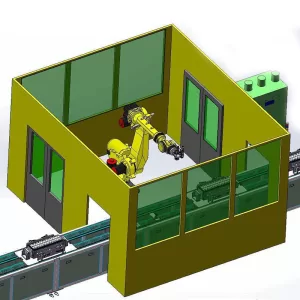

Process characteristics of prismatic aluminum shell battery module PACK assembly line:

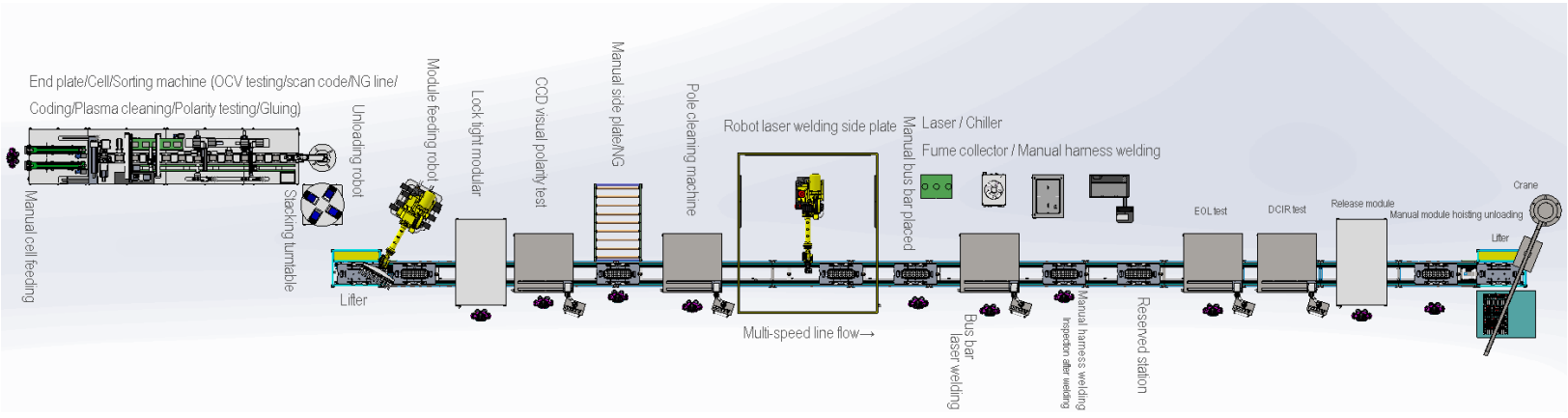

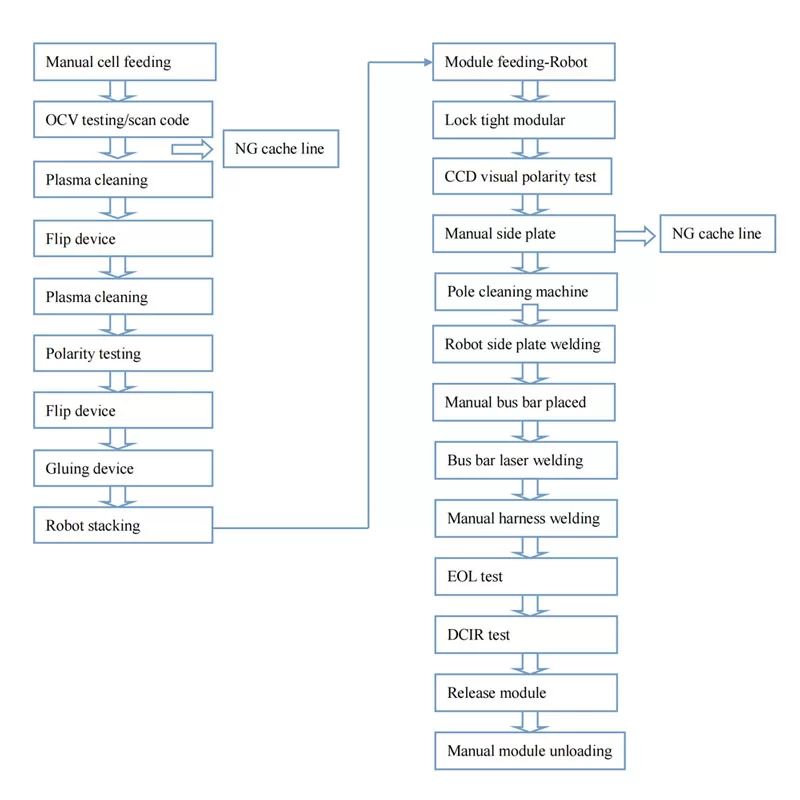

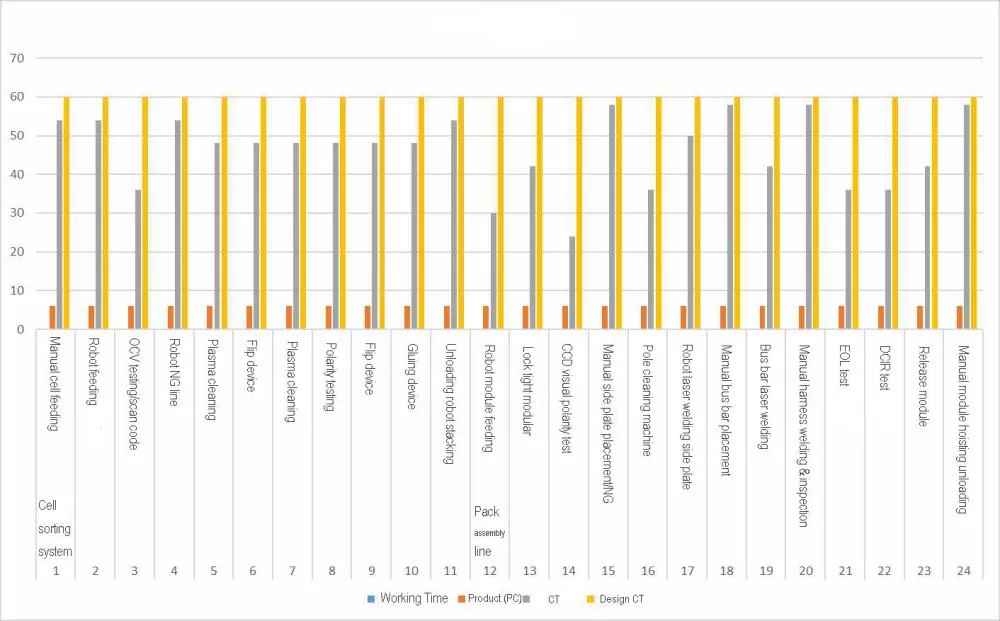

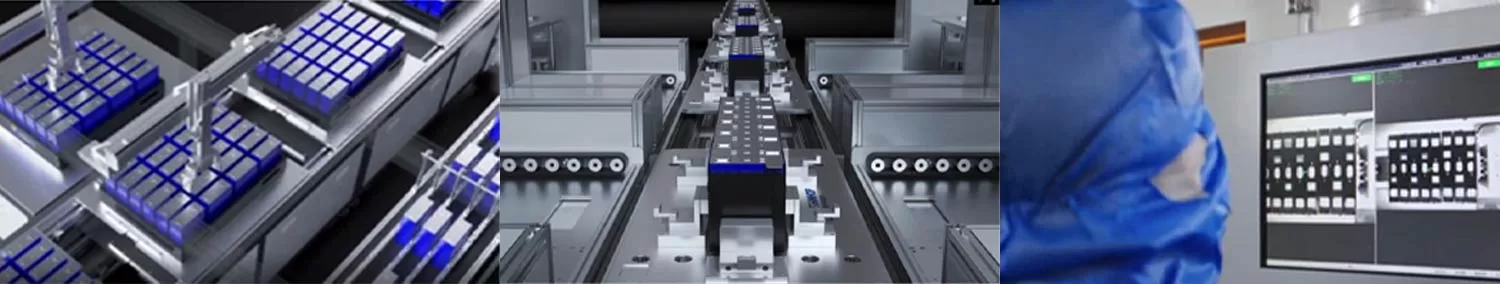

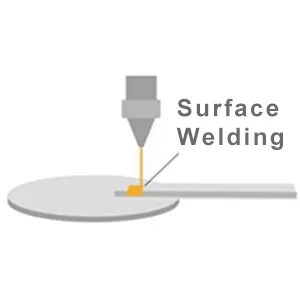

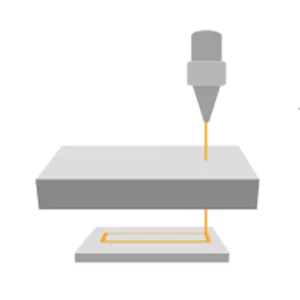

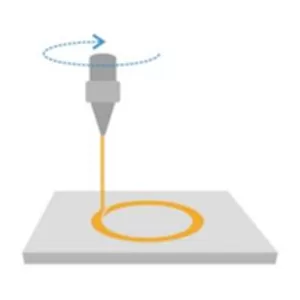

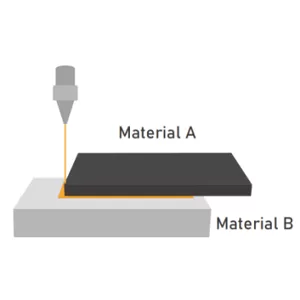

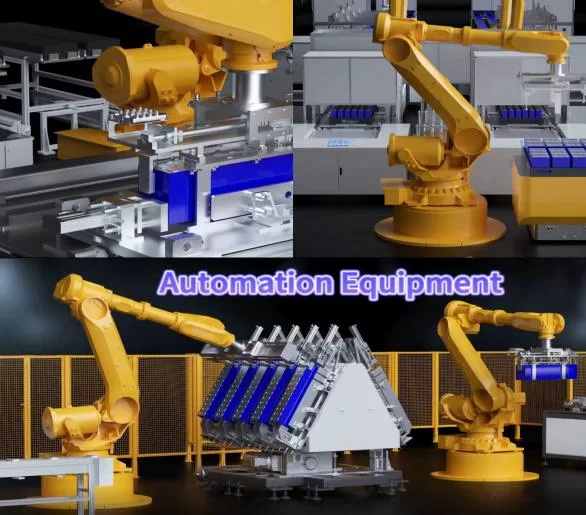

automatic loading, OCV test sorting, NG removal, cell cleaning, gluing, stacking, polarity judgement, automatic tightening, manual taping, automatic loosening, pole cleaning, manual aluminum rows (welded to the outside of the harness), laser welding, post-soldering inspection, EOL inspection, DCIR inspection, to PACK assembly line times the speed of the chain, manual assembly Testing… Smooth assembly process, high production efficiency and yield rate, suitable for large and medium-sized square aluminum shell battery PACK assembly needs.

Category Prismatic Battery Pack Assembly Line

Related Products

Related products

LEAVE A MESSAGE

If you have any questions, please leave a message for us.