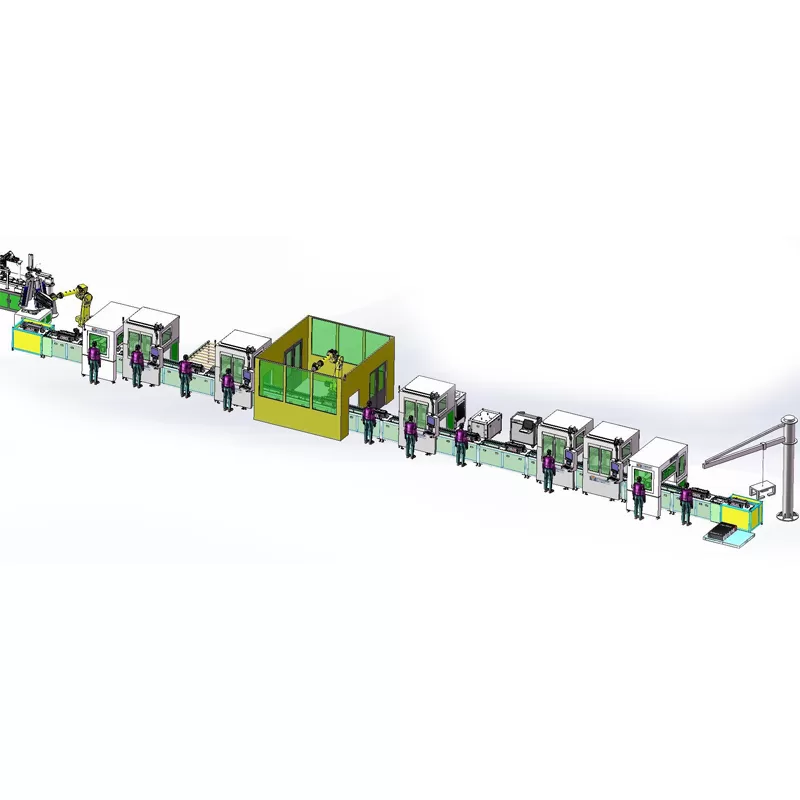

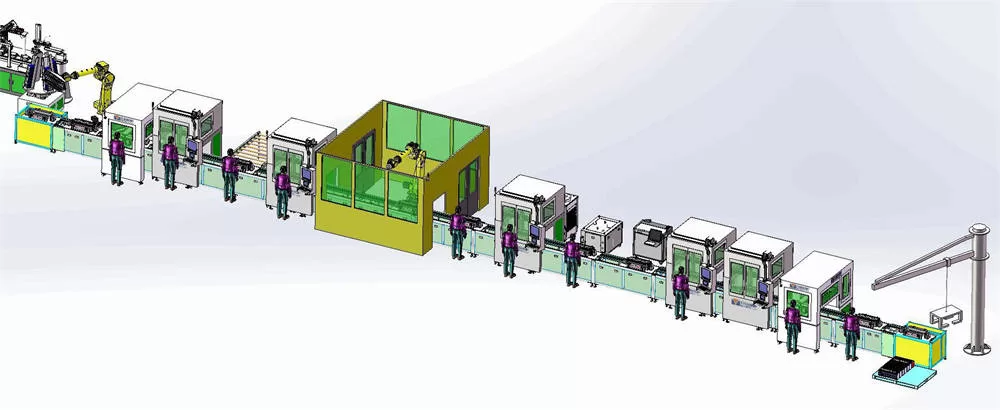

Overview

(The actual product is subject to the customer's product)

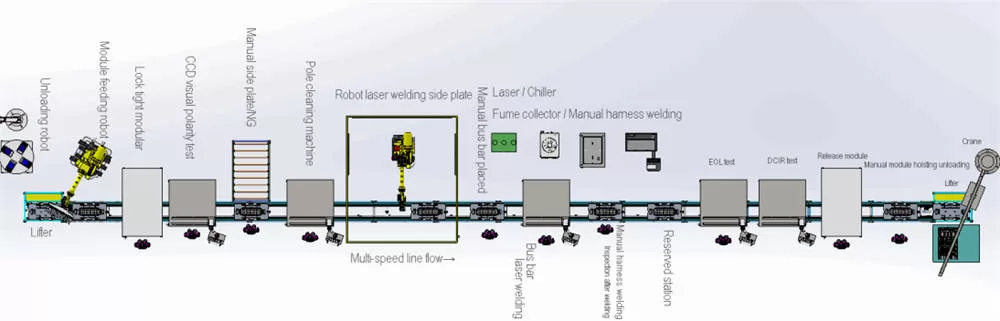

Process flow

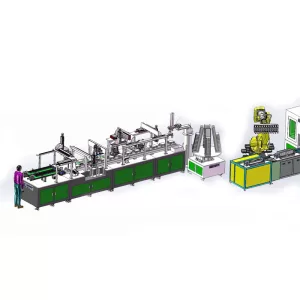

1 Feeding lifter – the empty tooling board returned from the lower layer is raised

to the upper layer and flows to the next station.

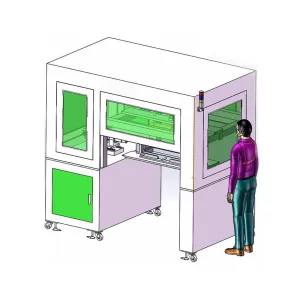

2 The upper double-speed conveyor is designed according to the product process and customer requirements.

3 Unloading lifter – the empty tooling board after the upper layer of cells is

removed, descend to the lower layer, and flow to the feeding lifer, so that the cycle works.

Configuration list

| S/N | Item | Brand | Quantity | Unit |

| 1 | Lifter | Airtac | 4 | Sets |

| 2 | 30.6M Assembly line | SHINHOP | 1 | Set |

| 3 | Tooling plate | SHINHOP | 19 | Pcs |

| 4 | Blocking device | Airtac | 15 | Pcs |

| 5 | Electrical device | Chint/ Schneider | 2 | Pcs |

| 6 | Inverter motor | JSCC | 2 | Pcs |

| 7 | PLC | Inovance/Mitsubishi | 2 | Pcs |

| 8 | Touch screen | Weinview | 2 | Pcs |

| 9 | Crane | SHINHOP | 1 | Pcs |