Overview

Note: MES port

(The actual product is subject to the customer's product)

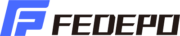

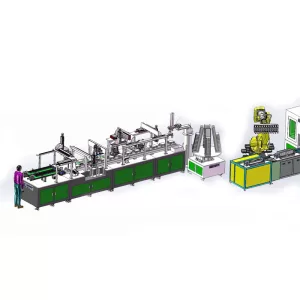

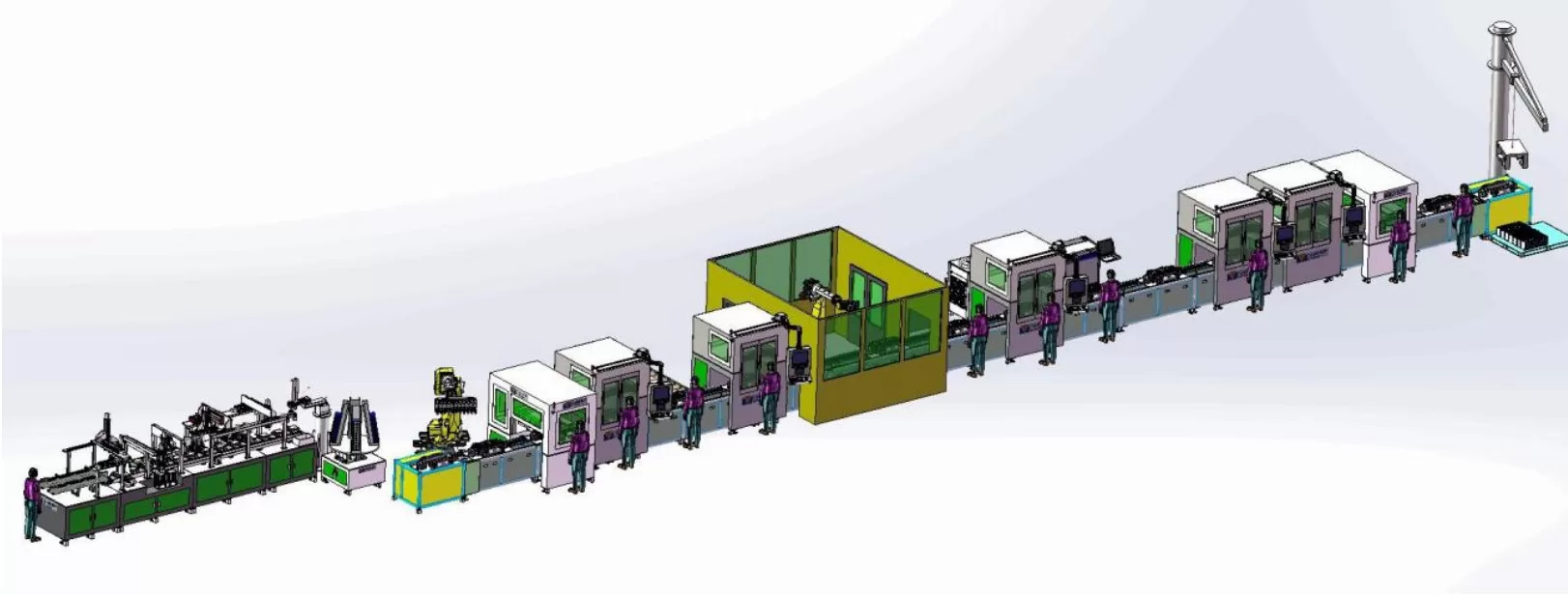

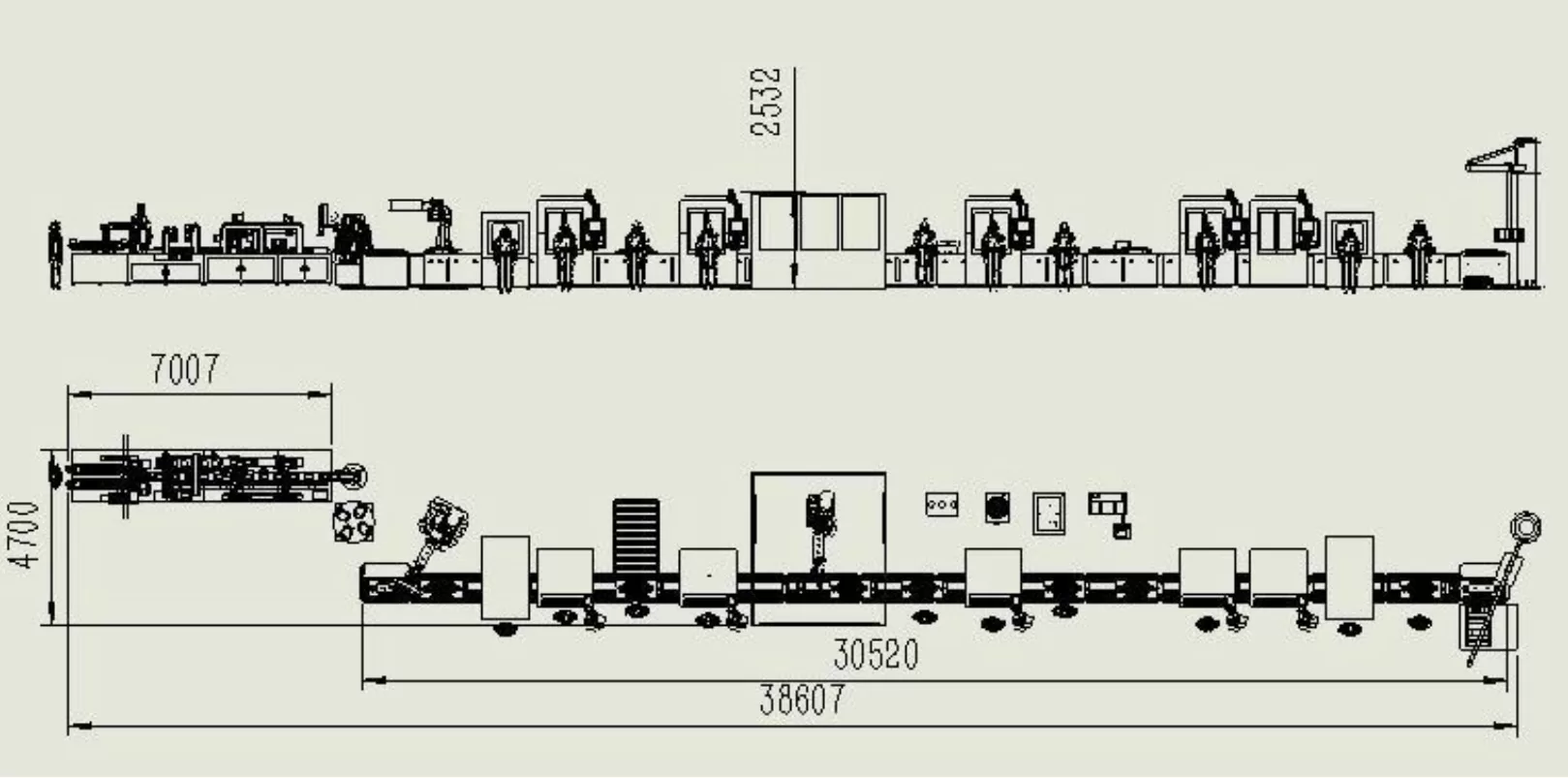

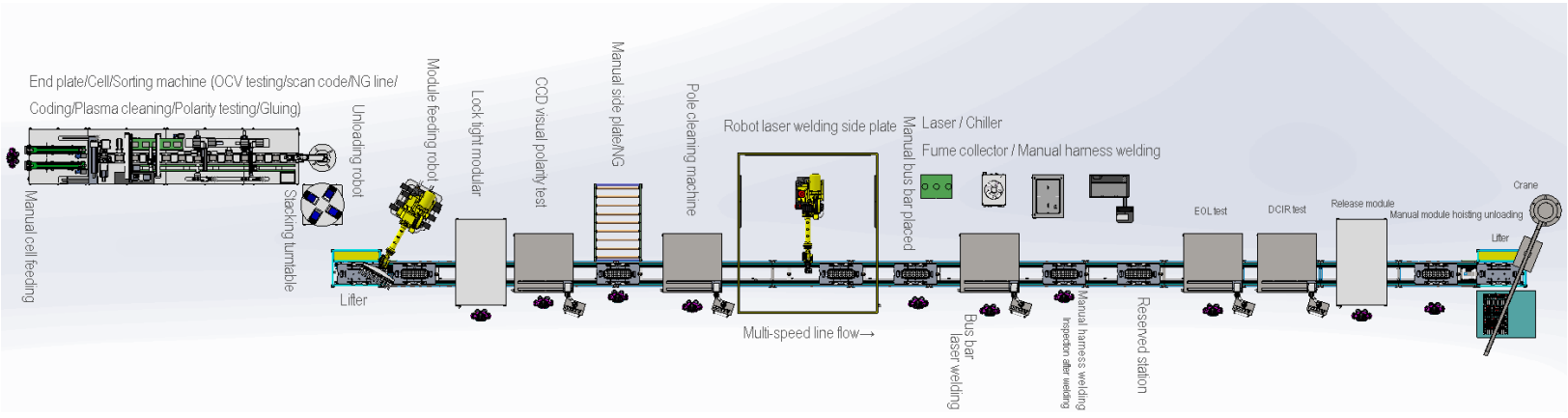

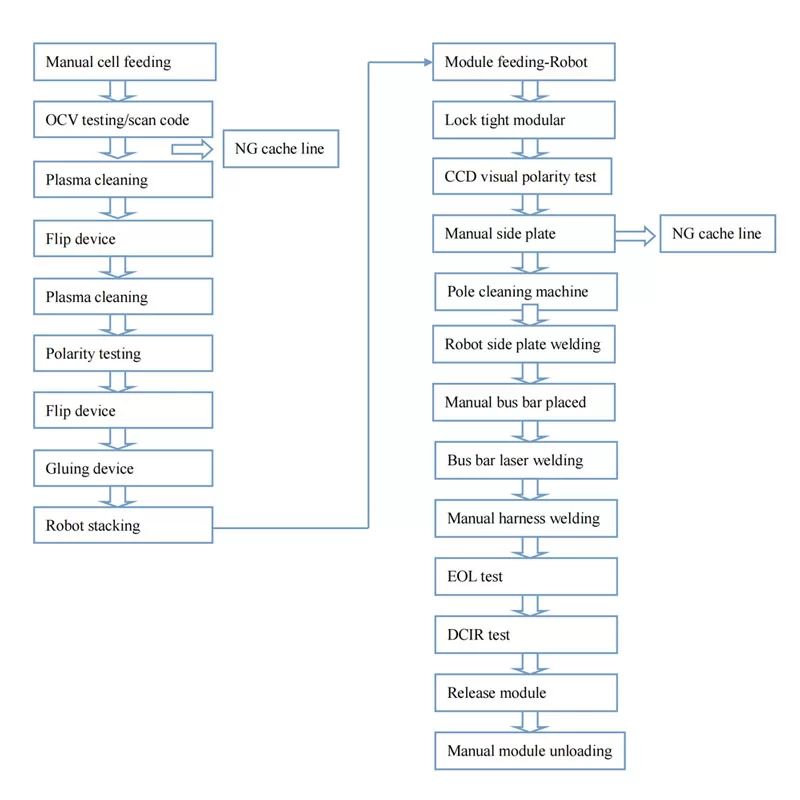

Assembly line-Path of action & production process flow

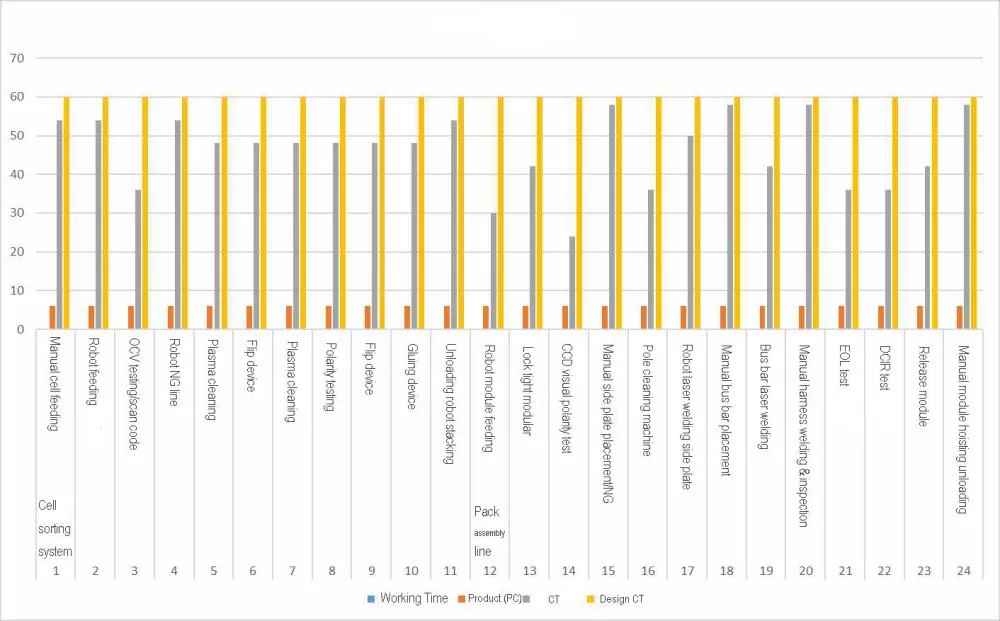

Design capacity-12S1P is design original version

| S/N | Item | Technology Process | Working Time | Channel (No.) | Machine (Set) | Product (PC) | CT | Design CT |

| 1 | Cell Sorting System | Manual cell feeding | 18S/2PCS | 2 | 1 | 6 | 54 | 60 |

| 2 | Robot feeding | 18S/2PCS | 2 | 1 | 6 | 54 | 60 | |

| 3 | OCV testing/scan code | 6S/1PCS | 1 | 1 | 6 | 36 | 60 | |

| 4 | Robot NG line | 9S/1PCS | 1 | 1 | 6 | 54 | 60 | |

| 5 | Plasma cleaning | 8S/1PCS | 1 | 1 | 6 | 48 | 60 | |

| 6 | Flip device | 8S/1PCS | 1 | 1 | 6 | 48 | 60 | |

| 7 | Plasma cleaning | 8S/1PCS | 1 | 1 | 6 | 48 | 60 | |

| 8 | Polarity testing | 6S/1PCS | 1 | 1 | 6 | 48 | 60 | |

| 9 | Flip device | 8S/1PCS | 1 | 1 | 6 | 48 | 60 | |

| 10 | Gluing device | 8S/1PCS | 1 | 1 | 6 | 48 | 60 | |

| 11 | Unloading robot stacking | 9S/1PCS | 1 | 1 | 6 | 54 | 60 | |

| 12 | Pack assembly line | Robot module feeding | 1 | 1 | 6 | 30 | 60 | |

| 13 | Lock tight modular | 1 | 1 | 6 | 42 | 60 | ||

| 14 | CCD visual polarity test | 1 | 1 | 6 | 24 | 60 | ||

| 15 | Manual side plate placement/NG | 1 | 1 | 6 | 58 | 60 | ||

| 16 | Pole cleaning machine | 1 | 1 | 6 | 36 | 60 | ||

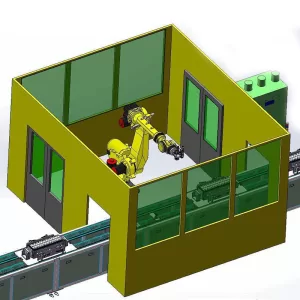

| 17 | Robot laser welding side plate | 1 | 1 | 6 | 50 | 60 | ||

| 18 | Manual bus bar placement | 1 | 1 | 6 | 58 | 60 | ||

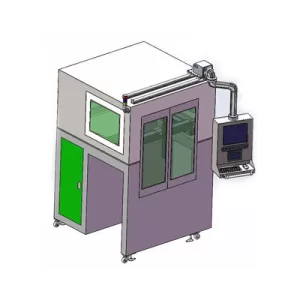

| 19 | Bus bar laser welding | 1 | 1 | 6 | 42 | 60 | ||

| 20 | Manual harness welding/Inspection after welding | 1 | 1 | 6 | 58 | 60 | ||

| 21 | EOL test | 1 | 1 | 6 | 36 | 60 | ||

| 22 | DCIR test | 1 | 1 | 6 | 36 | 60 | ||

| 23 | Release module | 1 | 1 | 6 | 42 | 60 | ||

| 24 | Manual module hoisting unloading | 1 | 1 | 6 | 58 | 60 |

The sorting machine processes cells is 6PPM.

The module capacity: 30UPH.

According to the equipment timing evaluation, if 10 hours is the capacity of 300 modules.

If the 0EE of the production line is 85%, the estimated capacity: 30*10*0.85=255 modules

(10 hours per shift).

Note: Manual part in red is estimated CT.