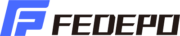

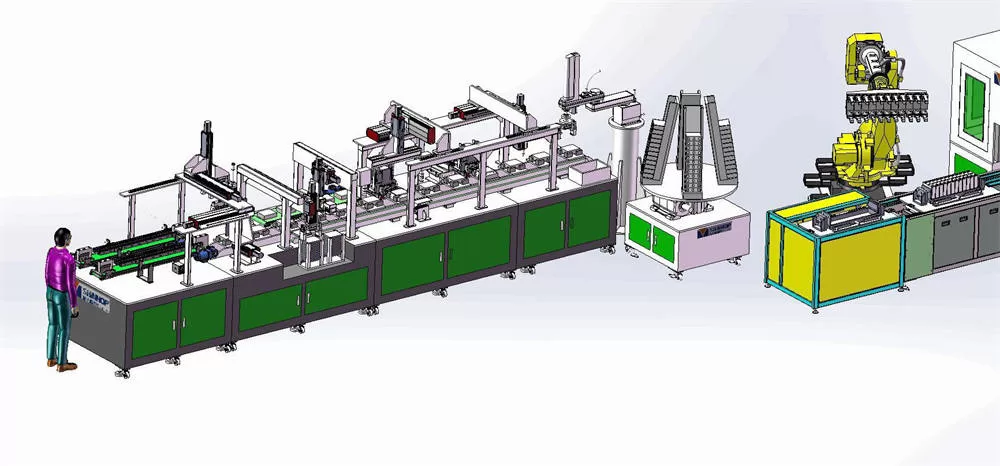

Overview

(The actual product is subject to the customer's product)

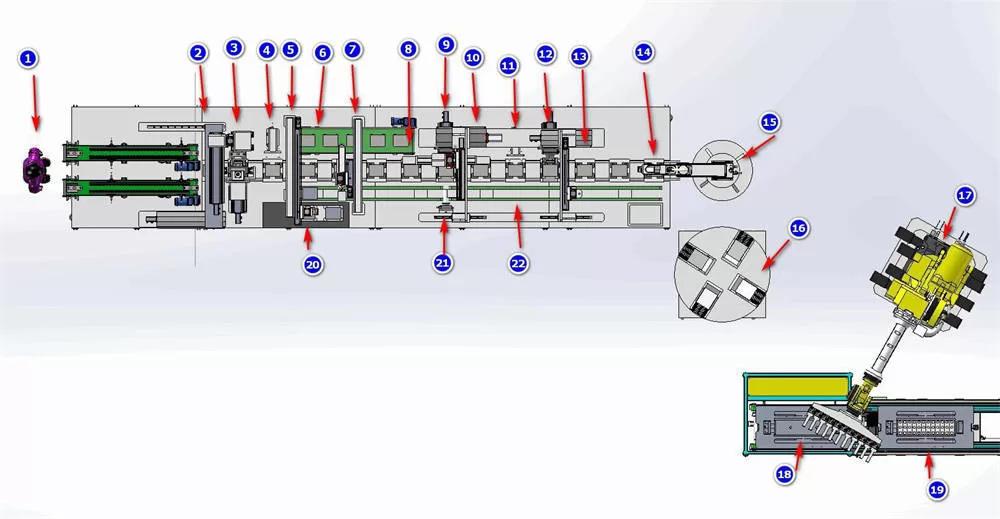

The meaning of the serial number in the figure:

1. Manual cell feeding station

2. Feeding robot

3. On line station

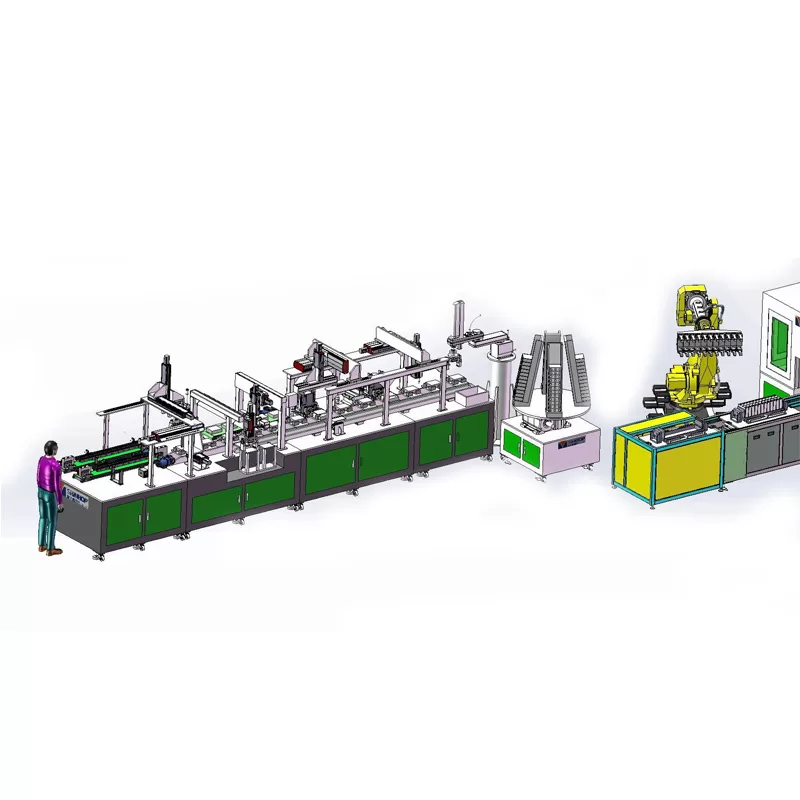

4. OCV testing/scan code station

5. NG robot station

6. NG line

7. Make Code

8. Plasma cleaning station

9. Flip station

10. Plasma cleaning station

11. Polarity testing station

12. Flip station

13. Gluing station

14. Unloading station

15. Unloading robot

16. Stacking rotating disk

17. Feeding robot

18. Lifter

19. Module feeding station

20. End plate station

21. Flip station

22 End plate line

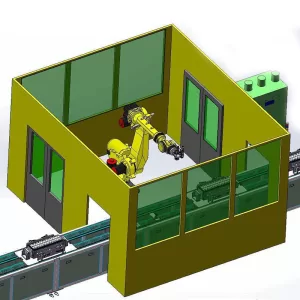

Process flow

Manual feeding cell position, double-assembly line feeding cell. After the

cell flows in station, the robot grabs it and moves it to the upper position to discharge the cell. OCV test after battery is in station. At the same time, scan the code to upload the system. According to the system command, whether the NG robot grabs the product to the NG cache line, the OK product is plasma cleaned at one side, the lower position is turned over, and the lower position is plasma cleaned for the other side. The polarity of the lower position is detected and uploaded, according to whether the lower position is reversed or not, after the lower position is glued, it waits at the unloading position, and the unloading robot selects.

If it is an end plate, the end plate line works as follows, the end plate

position is overlapped in advance, the feeding robot grabs the end plate and puts it on the end plate line, and flows to the inversion position. After the lower plasma is cleaned, the glue is applied and flows to the unloading station.

The unloading robot places the cells and end plates in the station of the

stacking rotary table in sequence, and after turning to the position, the feeding robot clamps the entire cell module and places the tooling plate in the loading position on the double-plus conveyor of the module.

OCV/IR Test Range and Accuracy

Test instrument: HIOKI 3562.

Equipment test resistance range: 0.01Ω -10Ω . Accuracy: +/﹣(0.5%rdg

+10dgt).

Equipment test voltage range: 0.0001V-60V. Accuracy: +/﹣(0.01%rdg

+3dgt).

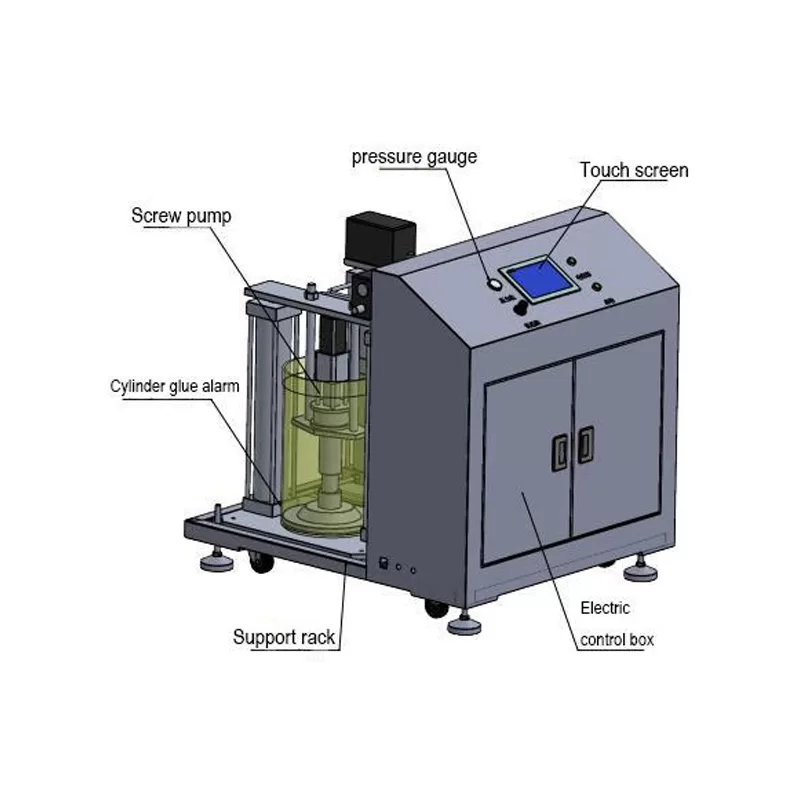

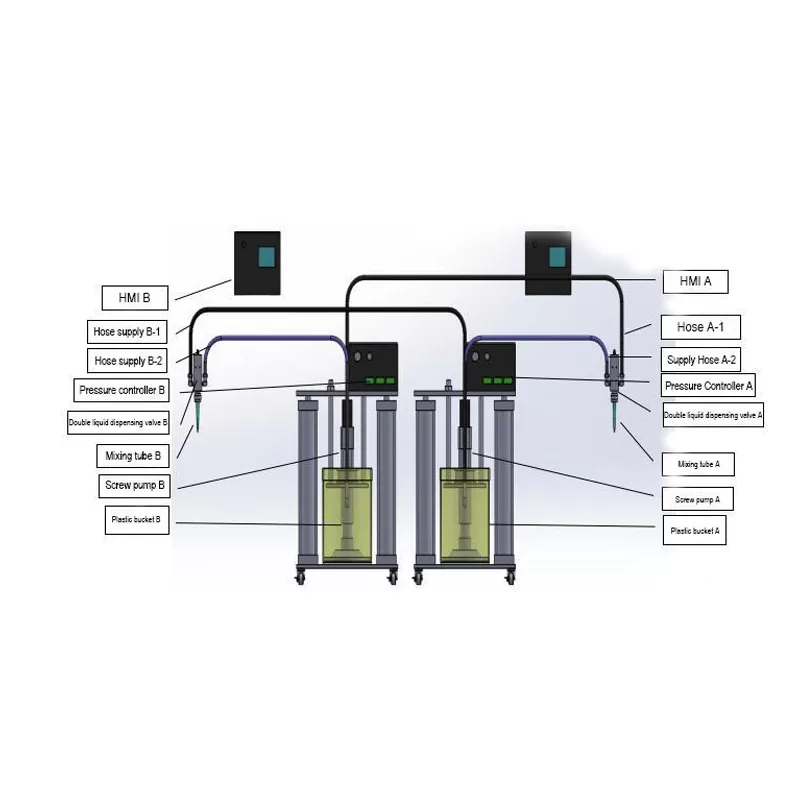

Glue machine parameters

| Item | Description |

| Model | JF-50 |

| Power | AC 200V/110V (50hz/60hz) |

| Max liquid output pressure | 6.0 Mpa, 60 bar (850 psi) |

| Air input pressure range | 243-700 kPa, 2.4-7.0 bar (35-100 psi) |

| Max liquid viscosity | 600,000 cps |

| Capacity per stroke (spread only on down stroke) | 5.0 cc (0.17 oz.) |

| Pushed speed for continuous operation | 40 cpm |

| Pushed max speed during operation | 60 cpm |

| Max flow (250,000 cps liquid) | 640 cc/min (32 oz/min); 0.162 ㎥/min (5.8 scfm) Air consumption 7 bar (100 psi) at 0.7 Pa |

| Stroke length | 19 mm (3/4 in.) |

| Pump max operating temperature | 60°C (140°F) |

| Air inlet size | 1/4 npt(f) |

| Liquid outlet size | 1/4 npt(f) |

| Weight | Approx. 65 kgs |

| Wetted parts | 304 and 17-4 pH Stainless Steel; PTFE, Viton, PEEK |

| Sound pressure level at 0.7 Mpa, 7bar (100 psi), 40cpm | 64.12 dB(A) |

Configuration list

| S/N | Item | Brand | Quantity | Unit |

| 1 | Belt line | SHINHOP | 5 | Pcs |

| 2 | Mechanical moving axis | Inovance | 17 | Pcs |

| 3 | On-line device | Airtac | 1 | Pcs |

| 4 | OCV testing device | HIOKI | 1 | Pcs |

| 5 | NG device / scan code | Keyence/ Hikvision | 1 | Pcs |

| 6 | Coding device | Raycus | 1 | Pcs |

| 7 | Plasma cleaning | SHINHOP | 2 | Pcs |

| 8 | Flip device | SHINHOP | 3 | Pcs |

| 9 | Glue device | SHINHOP | 1 | Pcs |

| 10 | End plate device | SHINHOP | 1 | Pcs |

| 11 | Stacking disk device | SHINHOP | 1 | Pcs |

| 12 | Device | SHINHOP | 5 | Pcs |

| 13 | Splitter | Hengzhun | 1 | Pcs |

| 14 | Unloading robot | YMAHA | 1 | Set |

| 15 | Feeding robot | ABB | 1 | Set |

| 16 | Tester | HIOKI | 1 | Pcs |

| 17 | IPcs + Display | SHINHOP | 1 | Pcs |

| 18 | Electric device | Chint/ Schneider | 1 | Pcs |

| 19 | PLC | Inovance/Mitsubishi | 2 | Pcs |

| 20 | Touch screen | Weinview | 2 | Pcs |